Cov khoom

Dental 5 Axis Milling Tshuab Rooj Dental Mills

Dental 5 Axis Milling Tshuab Rooj Dental Mills

Tom qab ob xyoos R&D, Yucera tso tawm ib qho kev tsim tshiab tshaj plaws cais cov hniav milling tshuab:

1. -Suitable rau zirconia blocks, PMMA, Wax thiab Composite khoom;

2. - Kab rov tav ua-ceev tuaj yeem nce li ntawm 20%;

3. - Kev saib xyuas yooj yim- Thaum lub tshuab tag nrho-hauv-ib qho tsis ua haujlwm, kev saib xyuas tom qab muag yuav nyuaj dua.Cov khoom sib cais tsuas yog yuav tsum tau hloov cov txheej txheem ua tiav kom tiav qhov hloov tshiab thiab kho;

4. -Tool detection sensor nrog 2um

5. -24hours on-line technical support

6. -Suav nrog hyperdent (dawb)

Technical parameter rau 5 axis milling tshuab:

| Axis | 5 Axis |

| Txiav Txoj Kev | qhuav milling |

| Cov khoom siv Milling | zirconia block, pmma, siv quav ciab, PEEK |

| Qhov loj ntawm cov khoom siv milling | φ98, thickness (10-30mm) |

| Ntau yam kev sib hloov & tling rotation | X / y / z: 105 / 135 / 90 A: 360 ° B: ± 30 ° |

| Ceev ntawm Thawj Tswj axis | 0-60000rpm / 500w |

| Tus tsav tsheb | Tag nrho kev sib hloov servo tsav tsav |

Kab rov tav ua VS Vertical machining:

1.Raws li tus thawj ruaj khov ntsug machining, kab rov tav milling tshuab

muab qhov nruab nrab ntawm lub ntiajteb txawj nqus qis dua.

2.Vertical thiab kab rov tav ua yog ob qho tib si cradle ua (Suitable rau me me precision qhov chaw ua).

Tsis muaj ntau qhov sib txawv ntawm ob qho no hauv kev teeb tsa

thiab kev ua hom, tab sis vim muaj kev ruaj ntseg zoo ntawm kev ua haujlwm kab rov tav, qhov ceev tuaj yeem nce ze li 20%

Txheeb xyuas cov plua plav tsis tu ncua, nyiam dua li ob mus rau peb hnub, ntxig cov yeeb nkab rau hauv lub qhov hauv qab ntawm lub tshuab nqus tsev, nias lub khawm plua plav thiab nqus.

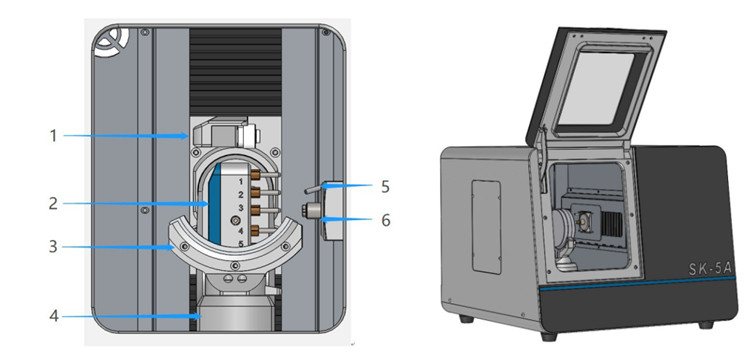

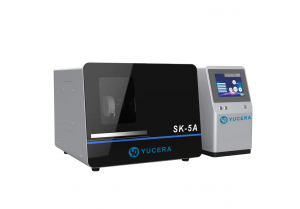

1. Riam setter 2.Tool library 3.Blank fixture and rotating shaftA 4.Axis of rotationB 5.Blowpipe 6.Spindle

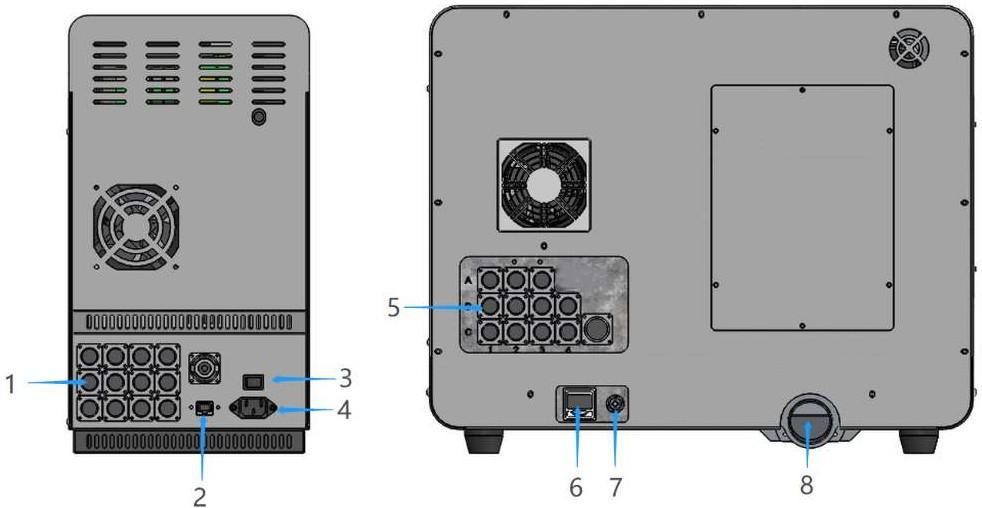

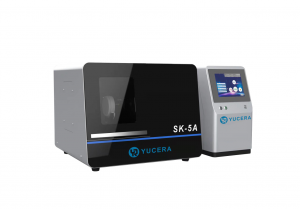

1.KAB HAUJ LWM HAUJ LWM HAUJ LWM 2.NETWORK POT 3.Power SWITCH

4.POWER CONNECTION 5.BUTT JOINT nrog tus tswv tsev 6.BAROMETER 7.AIR INLET 8.VACUUM PORT