Cov khoom

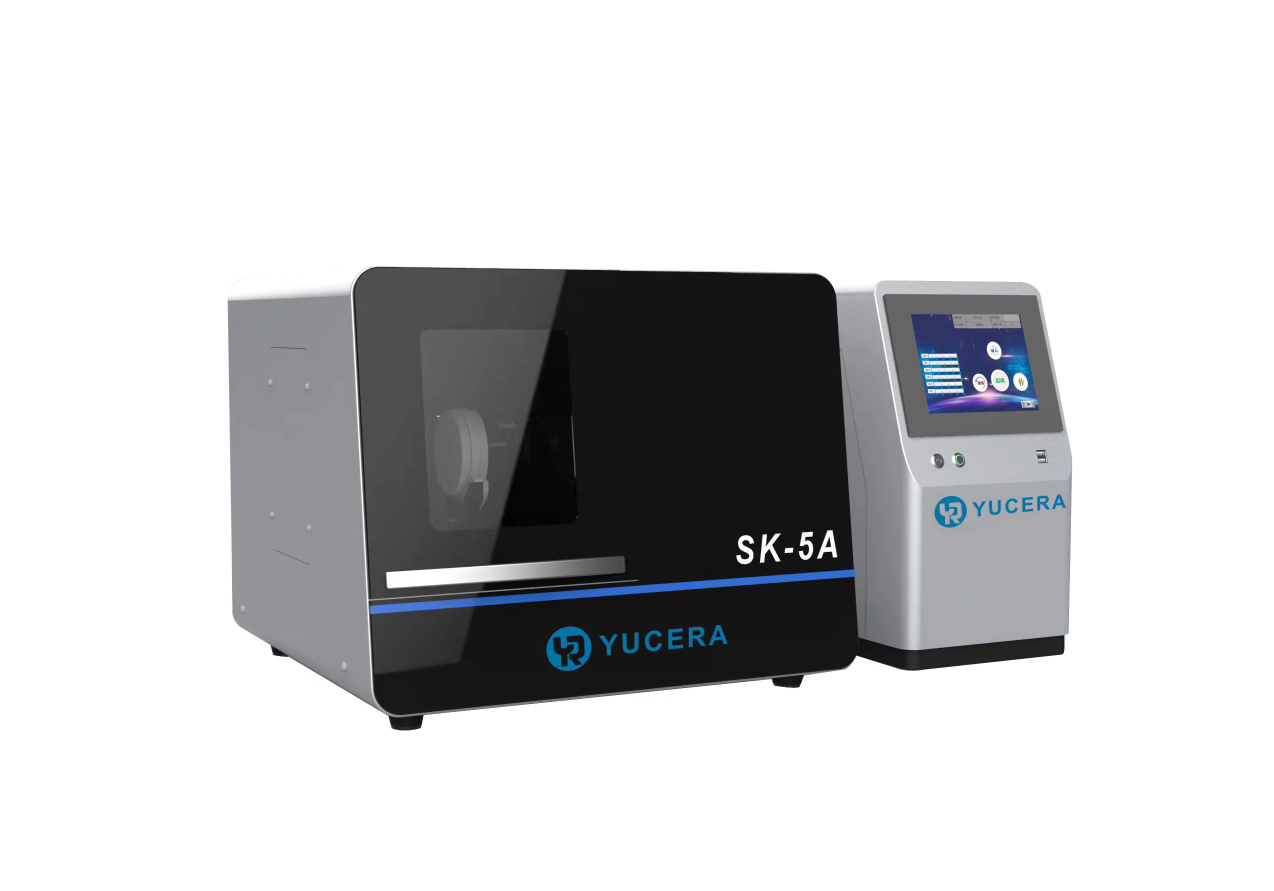

Tuam Tshoj Hoobkas Dental Zirconia Milling Tshuab CADCAM Dental Laboratory CNC Milling Tshuab

Tuam Tshoj Hoobkas Dental Zirconia Milling Tshuab CADCAM Dental Laboratory CNC Milling Tshuab

Shenzhen Yucera Dental Material Co., LTD yog ib lub tuam txhab ua lag luam tshwj xeeb hauv kev tsim, tsim thiab kev lag luam ntawm Hniav Zirconia Ceramic Block, sib xws CAD / CAM cov cuab yeej, thiab lwm yam khoom siv kho hniav.Raws li cov kws tshaj lij kev kuaj cov ntaub ntawv, peb tuaj yeem muab cov ntaub ntawv kho hniav digital, cov khoom siv kho hniav, thiab tag nrho cov khoom siv digital thiab cov kev pabcuam.

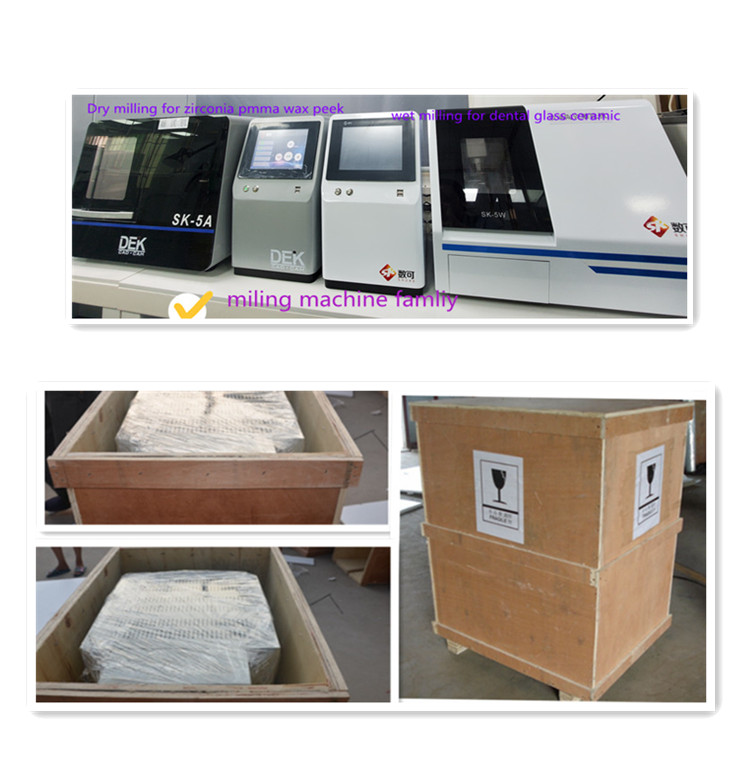

Yog vim li casno milling tshuab ib tug splited tsim:

1.Yog hais tias cov tsoos tag nrho-hauv-ib lub tshuab milling tshwm sim qee qhov teeb meem, kev saib xyuas tom qab muag yuav nyuaj dua.Tab sis peb lub tshuab milling sib cais tsuas yog yuav tsum tau hloov cov txheej txheem ua kom tiav cov kev hloov tshiab thiab kev saib xyuas;

2.Qhov kev tswj hwm yog cais los ntawm cov txheej txheem ua haujlwm kom txo qis kev puas tsuaj me ntsis rau cov khoom siv los ntawm cov plua plav

Vim li cas lub tshuab milling no yog kab rov tav ua:

1. Kab rov tav ua VS Vertical machining, Raws li tus thawj ruaj khov ntsug machining, kab rov tav txiav cov cuab yeej muab qhov nruab nrab ntawm lub ntiajteb txawj nqus qis dua.

2.Vertical processing thiab kab rov tav ua yog cradle processing, tsis muaj qhov sib txawv ntawm ob qho tib si hauv kev teeb tsa thiab kev ua haujlwm, tab sis vim muaj kev ruaj ntseg zoo ntawm kev ua haujlwm kab rov tav, kev ua haujlwm ceev tuaj yeem nce ze li 20%.

Qhov tseem ceeb techinical parameter:

| Ntev, dav thiab qhov siab | Txiav tshuab: 550 * 565 * 460mmLub cav loj: 450 * 250 * 450mm | Cov txheej txheem ua | Tsib-axis linkage, qhuav milling |

| hnyav | Txiav tshuab: 95KGMain cav: 20KG | Hom txheej txheem | Pem hauv ntej crowns, tag nrho cov crowns, txuas hniav, implant txuas hniav, implant qaum restorations, inlays, onlay, veneer, coping thiab lwm yam. |

| Rotating axis khiav lub kaum sab xis | A: 360 ° B: ± 30 ° | Main axis ceev | 0-60,000 rmp |

| Tag nrho lub zog | 800 W | Ua hauj lwm siab | 4.5-7.5bar (tsis muaj dej, tsis muaj roj av) |

| Txiav precision | 0.2 hli | Installation tej yam kev mob | Stable voltage: 220-230VCov huab cua ruaj khov ≥6.0bar Kub: 15-35 ℃ Tus txheeb ze humidity ≥80% |

| Cov cuab yeej magazine muaj peev xwm | 5 | Transmission interface | USB / Ethernet |

| Burs specifications | Cov khoom tshwj xeeb rau kov txoj kab uas hla 4mmTsis siv neeg hloov cuab yeej, tsis siv neeg lub cuab yeej nrhiav kom pom | Cov khoom siv Milling | zirconia blocks, PMMA, Wax, Composite khoom |

1.Sum: Kev saib xyuas tsis tu ncua thiab kev saib xyuas tuaj yeem ua kom cov cuab yeej ua haujlwm zoo thiab ua kom lub neej ua haujlwm..

2. Kev tu tsis tu ncua: Siv cov tshuaj ntxuav kom tsim nyog los ntxuav cov yas, thiab ceev faj tsis txhob siv rab phom cua los ntxuav sab hauv kom tsis txhob muaj plua plav thiab khib nyiab nkag mus rau hauv cov khoom siv tshuab.

3.Material fixture tu: Thaum muab cov khoom, xyuas kom meej tias cov fixtures thiab screws yog huv si kom pom clamping.

4.Main Axis Clip Cleaning: Tsis txhob tsuag tshuaj tsuag oily lossis compressed cua uas muaj roj thiab dej ncaj qha rau ntawm lub taub hau ntxaiv;lub spindle chuck thiab bur yuav tsum huv si.Kev nkag ntawm impurities tuaj yeem ua rau kev ua tsis tiav.

5.Nco ntsoov xyuas cov hoses, cables thiab kev sib txuas;