Products

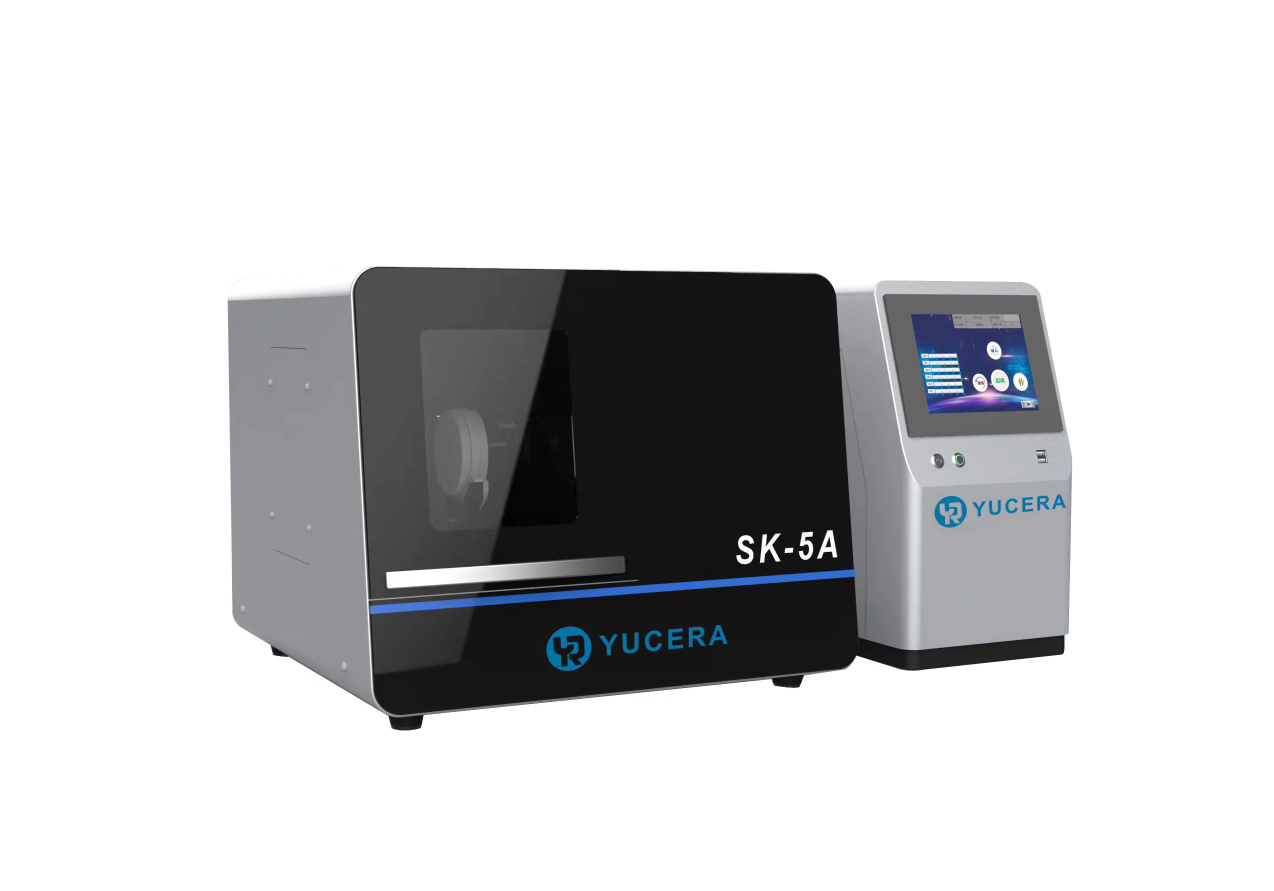

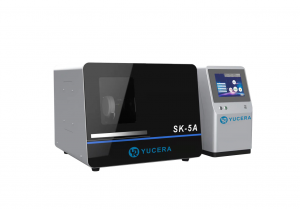

Chinese Factory Dental Zirconia Milling Machine CADCAM Dental Laboratory CNC Milling Machines

Chinese Factory Dental Zirconia Milling Machine CADCAM Dental Laboratory CNC Milling Machines

Shenzhen Yucera Dental Material Co., LTD is a comprehensive enterprise specializing in developing, manufacturing and marketing of Dental Zirconia Ceramic Block, corresponding CAD/CAM equipment, and other related dental products. As professional laboratory materials supplier, we can provide digital dental materials, dental equipment, and full range of digital products and services.

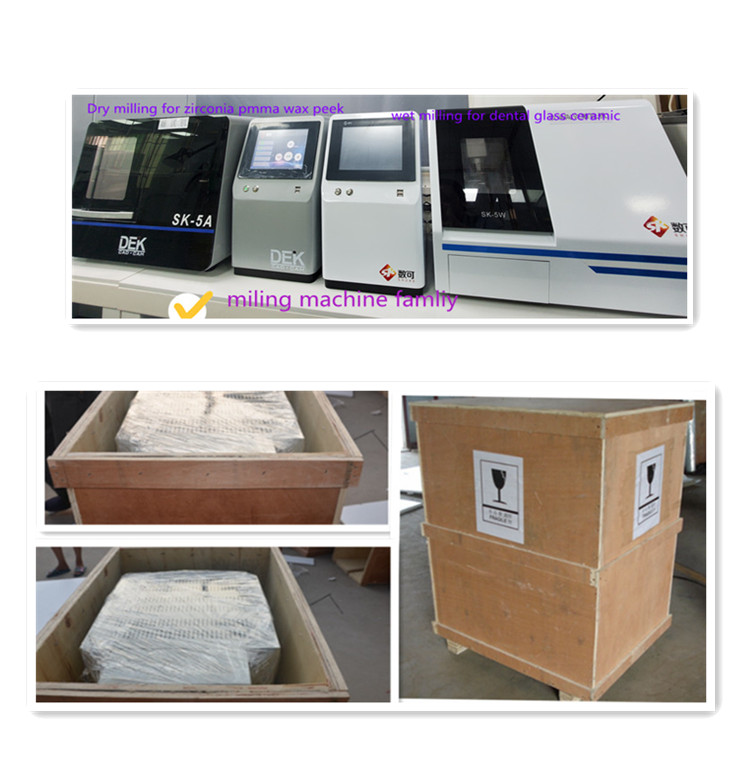

Why is this milling machine a splited design:

1.If the traditional all-in-one milling machine occure some problems, the after-sales maintenance is more complicated. But our split milling machine only needs to replace the processing system to complete the update and maintenance;

2.The control system is separated from the processing system to reduce the slight damage to the equipment caused by dust

Why is this milling machine is horizontal processing:

1.Horizontal processing VS Vertical machining,Based on the original stable vertical machining, the horizontal cutting equipment puts the center of gravity lower.

2.Vertical processing and horizontal processing are cradle processing,There is not much difference between the two in the layout and processing mode, but due to the excellent stability of horizontal processing,the processing speed can be increased by nearly 20%.

Key techinical parameter :

| Length, width and height | Cutting machine:550*565*460mmMain engine :450*250*450mm | Processing methods | Five-axis linkage, dry milling |

| weight | Cutting machine:95KGMain engine:20KG | Processable type | Inner crowns, full crowns, bridges, implant bridges, implant upper restorations, inlays, onlay, veneer, coping etc. |

| Rotating axis operating angle | A:360° B:±30° | Main axis speed | 0-60,000rmp |

| Total power | 800W | Working pressure | 4.5-7.5bar(no water, no gasoline ) |

| Cutting precision | 0.2mm | Installation conditions | Stable voltage:220-230V Stable air pressure≥6.0bar

Temperature:15-35℃ Relative humidity<80% |

| Tool magazine capacity | 5 | Transmission interface | USB/Ethernet |

| Burs specifications | Special props for handle diameter 4mmAutomatic tool change, automatic tool detection | Milling Materials | zirconia blocks , PMMA, Wax,Composite material |

1.Sum:Regular maintenance and maintenance can ensure the quality of equipment processing and increase service life..

2.regular cleaning:Use a suitable liquid detergent to clean the plastic part, and be careful not to use an air gun to clean the interior to prevent dust and debris from entering the mechanical parts.

3.Material fixture cleaning:When placing the material, ensure that the fixtures and screws are clean for optimal clamping.

4.Main Axis Clip Cleaning:Do not spray oily spray or compressed air containing oil and water directly on the spindle head; the spindle chuck and bur must be clean. The entry of impurities can cause processing failures.

5.Regularly check hoses, cables and connections;