Products

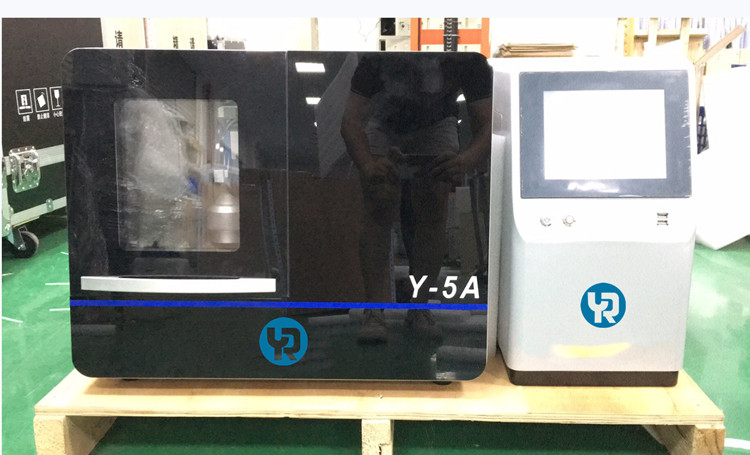

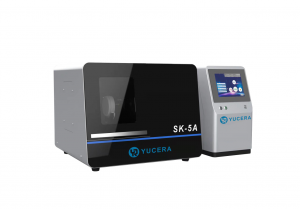

Yucera 5 Axis PMMA Dental Milling Machine For Zirconia Bloc

Yucera 5 Axis Dental Milling Machine For Zirconia Block, PMMA block, WAX Block Other Dental Equipment For CAD CAM System

Yucera 5 Axis Dental Milling Machine For Zirconia Block, PMMA block, WAX Block Other Dental Equipment For CAD CAM System

Detailed specification of 5 axis dental milling machine:

| Axis | 5 Axis |

| Cut Method | dry milling |

| Milling Materials | zirconia block, pmma, wax, PEEK |

| Size of milling materials | φ98, thickness(10-30mm) |

| Range of rotation & tling rotation | x/y/z: 105 / 135/ 90 A:360° B:±30° |

| Speed of Principal axis | 0-60000rpm / 500w |

| Driver | Full rotation servo motor drive |

| cutters | 5 tools; φ4mm |

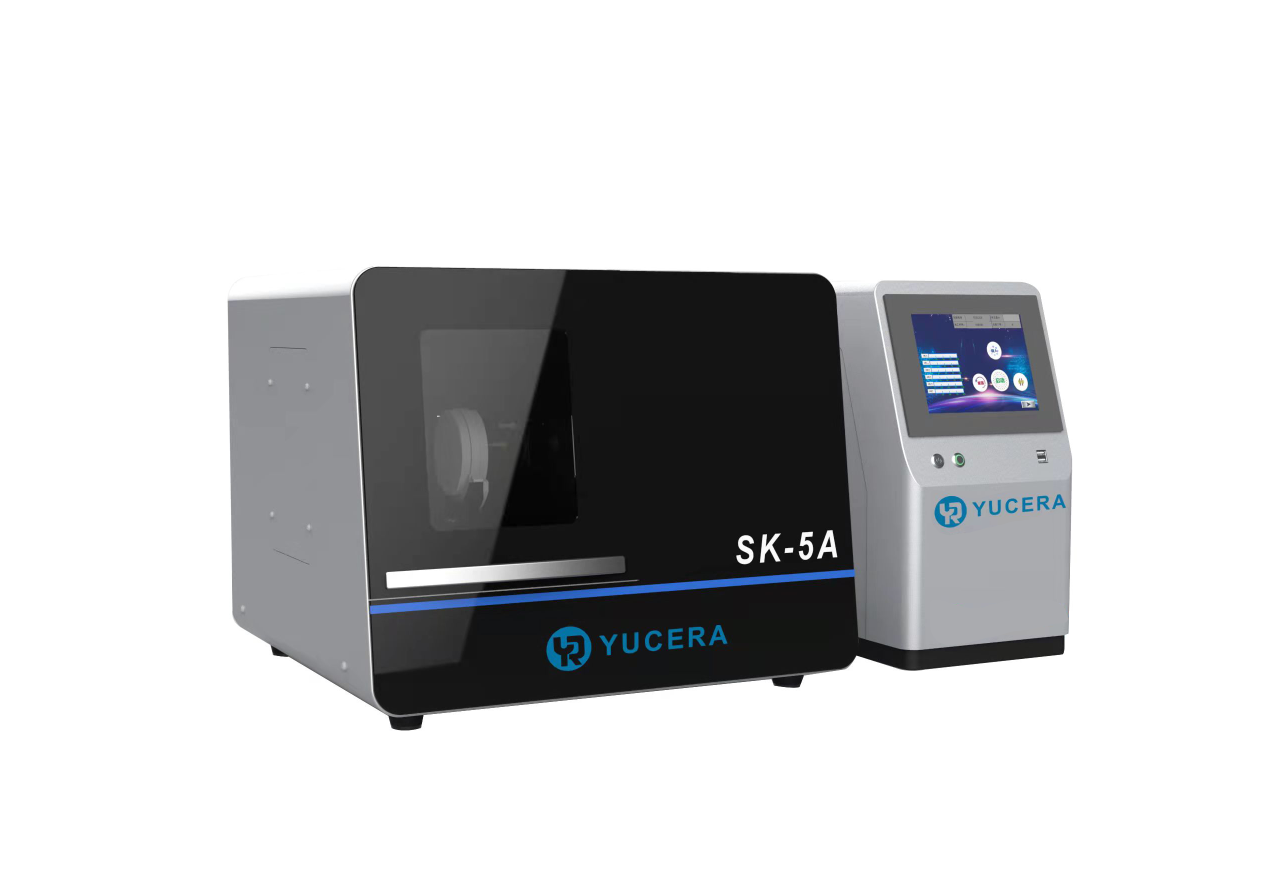

| size of dental 5aixs milling machine | CNC machine:55*56.5*46cm;Host milling machine:45*25*45cm |

| G.W: of dental 5aixs milling machine | CNC machine:95kg; Host milling machine:20kg |

| Compressed Air: | 4.5-7.5bar;50ml/min |

| Min Capacity-Dry: | 3000L/min |

| Power requirement : | 800W;220-230v AC,56/60 hz |

Advantage of 5 axis dental milling machine:

1. Horizontal processing-speed can be increased by nearly 20%

2. simplifying maintenance- When the all-in-one machine fails, the after-sales maintenance is more complicated. The split equipment only needs to replace the processing system to complete the update and maintenance;

3.Tool detection sensor with 2um

4.24hours on-line technical support

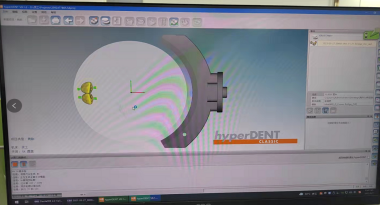

5.include hyperdent(free)

*Horizontal processing VS Vertical machining,Based on the original stable vertical machining, the horizontal cutting equipment puts the center of gravity lower.

*Vertical processing and horizontal processing are cradle processing,There is not much difference between the two in the layout and processing mode, but due to the excellent stability of horizontal processing, the processing speed can be increased by nearly 20%.

Why is Yucera-5A a split design?(Dental CAD CAM 5 Axis Milling Machine)?

Easy to maintain:

*When the all-in-one machine fails, the after-sales maintenance is more complicated. The split equipment only needs to replace the processing system to complete the update and maintenance;

*The control system is separated from the processing system to reduce the slight damage to the equipment caused by dust

How many teeth can SK-5A cut at one time?(Dental CAD CAM 5 Axis Milling Machine)

Innovative fixture design, compared with a metal fixture, the utilization rate of porcelain blocks is increased by 30%

Introduction for 5 axis dental zirconia milling machine:

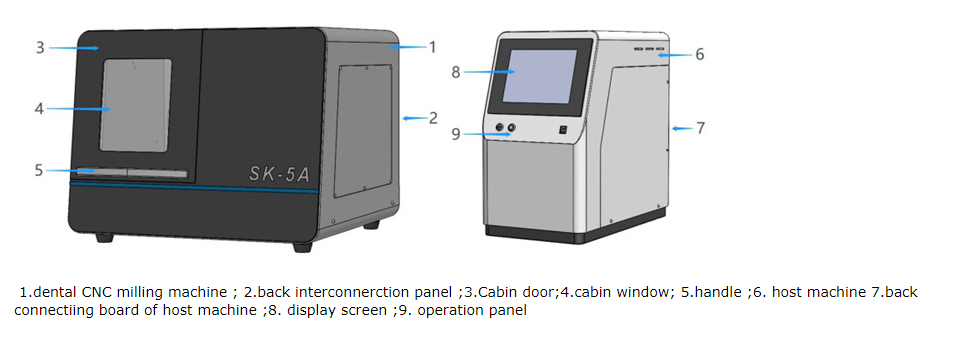

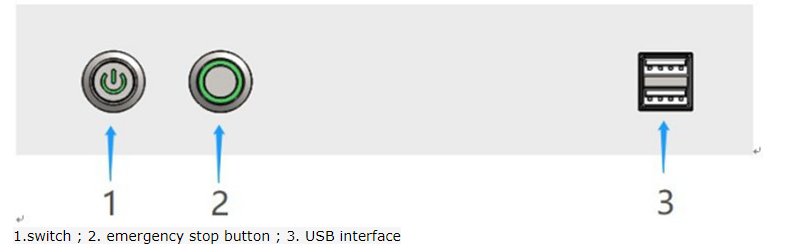

Description for operation panel of 5 axis denal milling machine :

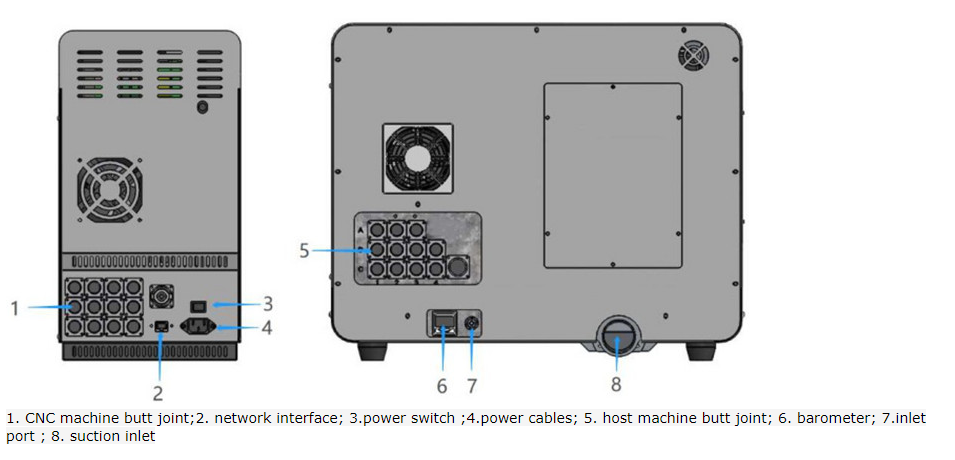

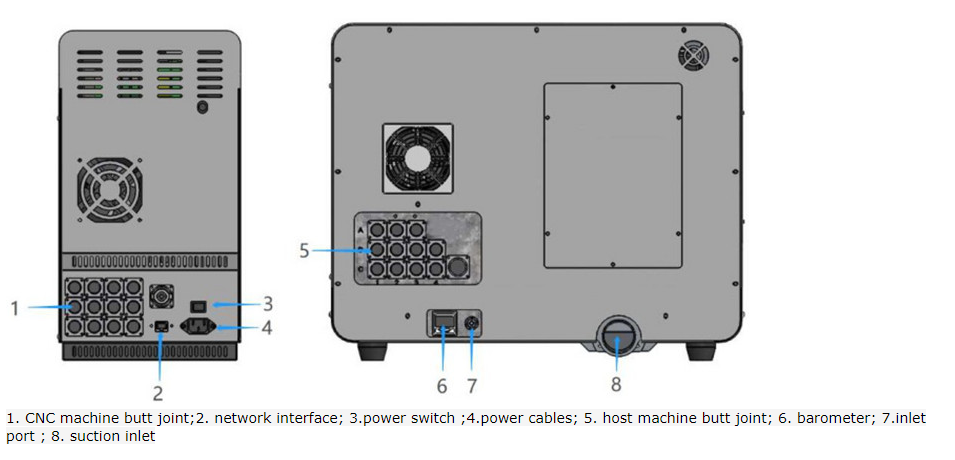

Description for back operation connection plate of 5 axis denal milling machine :

Description for working cabin of CAD CAM 5 axis dental milling machine:

FAQ:

1. Q: Are you a factory or trading company?

A: We’re the manufacture provide the most competitive products, always here to help you win the markets.

2. Q: How to pay the money for dental 5 axis milling machine?

A: We can accept payment methods by TT / Western Union/LC. (transfer fee charge to buyer)Others PolicySample Policy: We can offer sample without free.

3. Q: What’s the price term for dental 5 axis milling machine?

A: We offer the EXW / FOB /CIF price, for the high risk and unstable fuel prices, hope you can understand us.

4. Q: What’s the shipment method for dental 5 axis milling machine ?

A: 1st choice: It can be Ocean Shipping, Airlift o Express (EMS, UPS, DHL, TNT, and FEDEX). So before placing order .please contact us to confirm.About 5 -7working days by express.

2nd choice: If you have your forwarder in China, we can send the goods to the warehouse according to your forwarder Booking Form.