5-axis milling technology has revolutionized zirconia restorations in dental CAD/CAM workflows, offering unparalleled precision, efficiency, and versatility. Unlike 3- or 4-axis systems, 5-axis machines enable simultaneous multi-directional machining, allowing complex undercuts, angled implants, and intricate geometries without repositioning. This is particularly vital for zirconia—a durable, biocompatible material favored for crowns, bridges, veneers, inlays, onlays, and implant abutments due to its strength (>1000 MPa flexural) and natural translucency.

In the Asia Pacific (APAC) region, 5-axis milling adoption in zirconia restorations is surging as of 2026, driven by rapid digital dentistry growth, dental tourism, and expanding lab infrastructure. APAC leads global momentum with CAGRs of 8-10% in related markets, outpacing mature regions like North America. This article delves into key applications, technological benefits, regional trends, drivers, challenges, and future outlook for 5-axis milling in zirconia restorations across APAC.

Core Applications of 5-Axis Milling in Zirconia Restorations

- Crowns and Single-Unit Restorations 5-axis milling excels in producing monolithic zirconia crowns with precise marginal fit (accuracy to 10-20 μm) and natural occlusal anatomy. The technology’s rotational axes (+35°/-91° B-axis range typical) allow detailed surface texturing and esthetic layering, reducing post-milling adjustments. In APAC, where cosmetic dentistry demand is high, this supports anterior restorations with enhanced translucency.

- Bridges and Multi-Unit Frameworks For 3-6 unit bridges, 5-axis systems handle connector stability and uniform thickness (minimum 0.5-1 mm), minimizing fracture risks. Simultaneous machining ensures even stress distribution, critical for posterior load-bearing zirconia. Applications extend to hybrid bridges combining zirconia frameworks with veneering ceramics.

- Implant Abutments and Bars Angled implants (up to 90° vertical milling) benefit from 5-axis precision, enabling custom abutments with accurate emergence profiles and screw channels. This is essential in APAC’s growing implant market, where zirconia abutments offer biocompatibility and reduced plaque accumulation.

- Veneers, Inlays, and Onlays Thin zirconia veneers (0.3-0.5 mm) require fine detail; 5-axis milling achieves smooth margins and internal adaptations, enhancing bond strength and longevity. The technology supports conservative preparations, aligning with minimally invasive trends.

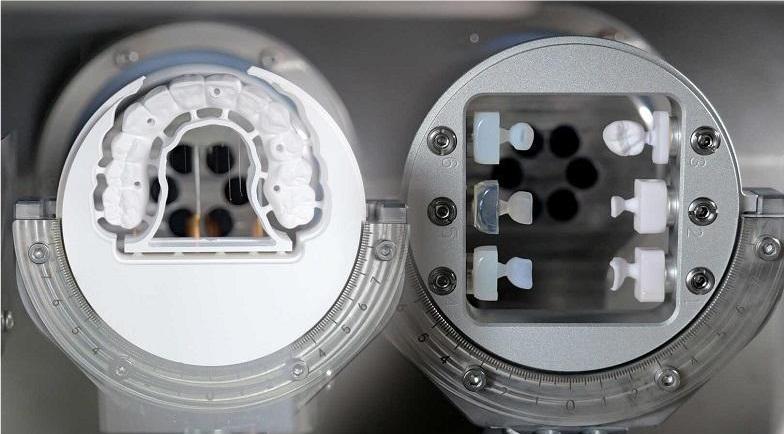

- Full-Arch Prosthetics and Dentures For overdentures or full zirconia arches, 5-axis machines process large discs (Ø98 mm) with complex contours, improving fit over edentulous ridges.

These applications leverage zirconia’s properties, with 5-axis milling reducing cycle times by up to 40% compared to simpler axes, boosting lab productivity.

Technological Benefits in Zirconia Processing

- Precision and Surface Quality With micron-level accuracy (0.01 mm cutting), 5-axis milling minimizes chipping and ensures smooth finishes, reducing manual polishing and improving cementation. Adoption in 45% of dental labs enables 10-micron precision for complex geometries.

- Efficiency and Speed High-speed spindles (up to 60,000 RPM) and automatic tool changers (7-18 tools) process zirconia discs quickly—single crowns in <15 minutes, bridges in <30 minutes. This integrates with fast sintering for same-day workflows.

- Material Utilization Optimized nesting algorithms maximize disc usage (up to 30% more efficient), reducing waste in cost-sensitive APAC markets.

- Versatility Compatible with various zirconia types (high-strength, translucent), 5-axis systems handle dry milling for zirconia, extending to PMMA, wax, and PEEK for temporaries.

These benefits enhance restoration durability, with zirconia survival rates >95% over 5-10 years in clinical studies.

Regional Trends and Adoption in APAC

The APAC dental CAD/CAM market, including 5-axis milling, is projected to grow from USD 1.1 billion in 2023 to USD 2.09 billion by 2031 at 8.3% CAGR, with zirconia restorations driving demand. The global 5-axis dental milling machine segment anticipates 9.6% CAGR from 2026-2033, with APAC contributing significantly due to manufacturing hubs.

China dominates, with urban labs in Shanghai and Beijing adopting 5-axis for high-volume zirconia crowns. Domestic production lowers costs, supporting export and local use in cosmetic procedures.

India shows explosive growth, fueled by dental tourism in Mumbai and Bangalore. Affordable 5-axis systems enable precise zirconia bridges for international patients, with market expansion in Tier-2 cities.

Japan emphasizes precision for aging populations, using 5-axis for implant zirconia abutments in Tokyo clinics. Government digital initiatives drive adoption.

South Korea focuses on esthetics, with 5-axis milling for translucent zirconia veneers in cosmetic-heavy practices.

Southeast Asia (Thailand, Indonesia) benefits from tourism, where 5-axis enhances same-day zirconia restorations in Bangkok labs.

Urban private labs lead (70-80% penetration), while rural areas emerge as costs decline.

Key Drivers of Adoption

- Digital Dentistry Boom Integration with intraoral scanners and CAD software streamlines zirconia workflows, reducing turnaround from days to hours.

- Zirconia Market Growth APAC zirconia materials expand at double-digit rates, with 5-axis enabling advanced multilayer blocks for natural gradients.

- Economic Factors Rising middle classes and dental tourism demand efficient, high-quality restorations.

- Technological Accessibility Compact, affordable 5-axis machines (dimensions ~530×650×750 mm) fit chairside setups.

- Sustainability Reduced waste and energy use align with regional green initiatives.

Challenges and Solutions

- Cost Barriers Initial investments (USD 50,000-150,000) limit small clinics; solutions include leasing and local manufacturing.

- Training Needs Skill gaps in emerging markets; addressed via online modules and certifications.

- Material Compatibility Ensuring zirconia quality; resolved with standardized blocks.

- Regulatory Variations Harmonizing standards across APAC facilitates adoption.

Future Outlook to 2030

By 2030, APAC 5-axis milling in zirconia is expected to grow at 9-10% CAGR, contributing 30% to global markets. Trends include AI-optimized tool paths, hybrid wet/dry modes, and multi-material processing. China and India will drive volume, Japan precision innovations.

Conclusion

5-axis milling technology is transforming zirconia restorations in Asia Pacific, offering precision, speed, and versatility for crowns, bridges, and implants. As adoption surges in China, India, Japan, and beyond, it enhances CAD/CAM efficiency and patient outcomes.

Dental labs and clinics embracing 5-axis will gain competitive advantages in this dynamic market. Monitor advancements in materials and integration to optimize workflows in the digital dentistry era.

Post time: Feb-09-2026