Cov khoom

Kev Kho Hniav Lithium Disilicate Nrog Siab Translucent thiab iav Ceramic Blocks rau Dental Lithium Dislicate Blocks

Kev Kho Hniav Lithium Disilicate Nrog Siab Translucent thiab iav Ceramic Blocks rau Dental Lithium Dislicate Blocks

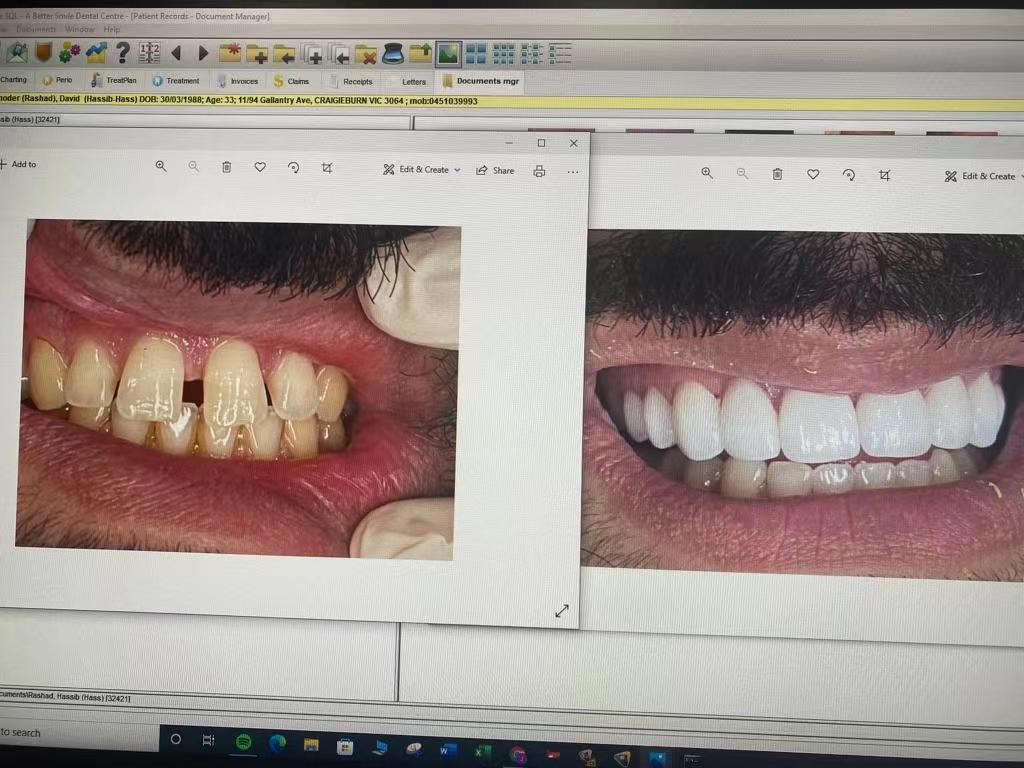

Kho Hniav iav Ceramic yog lub rooj zaum digital nrov thoob plaws ntiaj teb cov khoom siv ceramic, uas yooj yim rau zeb thiab crystallization txheej txheem tsuas yog siv sijhawm 20 feeb, nrog rau CAD / CAM system ntawm kev ua haujlwm siab, cov txheej txheem ntau lawm yog qhov sib txuam, siab heev kom ua tiav kev kho tam sim;superior transparency, nthuav qhia cov nyhuv bionic zoo nkauj heev.

Specification ntawm cov hniav lithium disilicate blocks:

1. Xim: VITA16, bleach dawb 4 (BL1/BL2/BL3/BL4)

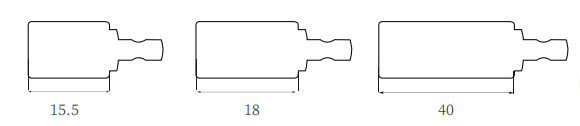

2.Size: 15.5 * 11 * 13 (I12);18 * 13 * 15 (C14);40 * 15 * 14 (B40)

3.Transparency: HT (siab pob tshab) thiab LT (tsis tshua muaj pob tshab)

4.Suitable rau: ntau yam mandrels xaiv los ntawm, tuaj yeem phim ntau lub tshuab milling.

Sintering nkhaus rau cov hniav lithium disilicates:

| Qhov pibkub | Lub sij hawm ziab | Cua sov tus nqi | Qhov siab tshajkub | Qhov siab tshajkub | Qhov kawgkub |

| 450 ℃ | 4 min | 40 ℃ / min | 840 ℃ | 6 min los yog 2 min | 300 ℃ |

Kev Xaiv Kev Kho Hniav Lithium Disilicate Blocks:

1. Monolithic ua los yog ib nrab ceramic veneering

2. yeem txhuam los yog dipping infiltration ua tau

Qhov zoo ntawm cov hniav lithium disilicate blocks:

1.Txhim kho lub zog zoo: peb lub ntsiab lus dabtsi yog khoov lub zog tau nce mus rau 400 ± 60 MPa, tso cai rau CAD / CAM system los tsim nrog cov neeg siab dua, txo cov txheej txheem nyuaj ntawm ultra-thin veneer thiab lwm yam.restorations, thiab txhim kho lub zog thiab kev ruaj ntseg ntawm cov ntaub ntawv zaum nyob rau hauv lubQhov ncauj

2.Simulate hardness ntawm ib tug tej yam ntuj tso hniav: piv nrog rau lwm yam ntaub ntawv, hardness ntawm Cameo iav ceramics yog ze rau cov natural tib neeg cov hniav, uas yuav txo tau cov ntau heev hnav ntawm occlusion hniav tshwm sim los ntawm hardness txawv, thiab tswj. qhov abrasion ntawm cov restoration thiab cov hniav nyob ib puag ncig

3.Zuag qhia tag nrho kev noj qab haus huv, yooj yim los teeb tsa: cov qauv kev tshawb fawb nanosmicron crystallization muab kev ruaj ntseg zoo dua qub thiab cov txheej txheem raug rau milling kho, ua kom yooj yim rau kev ua haujlwm ntawm cov rooj zaum rov qab thiab polishing, thiab paub txog qhov zoo haum ntawm tus kws kho cov kev ua thiab kev kho cov hniav.