Products

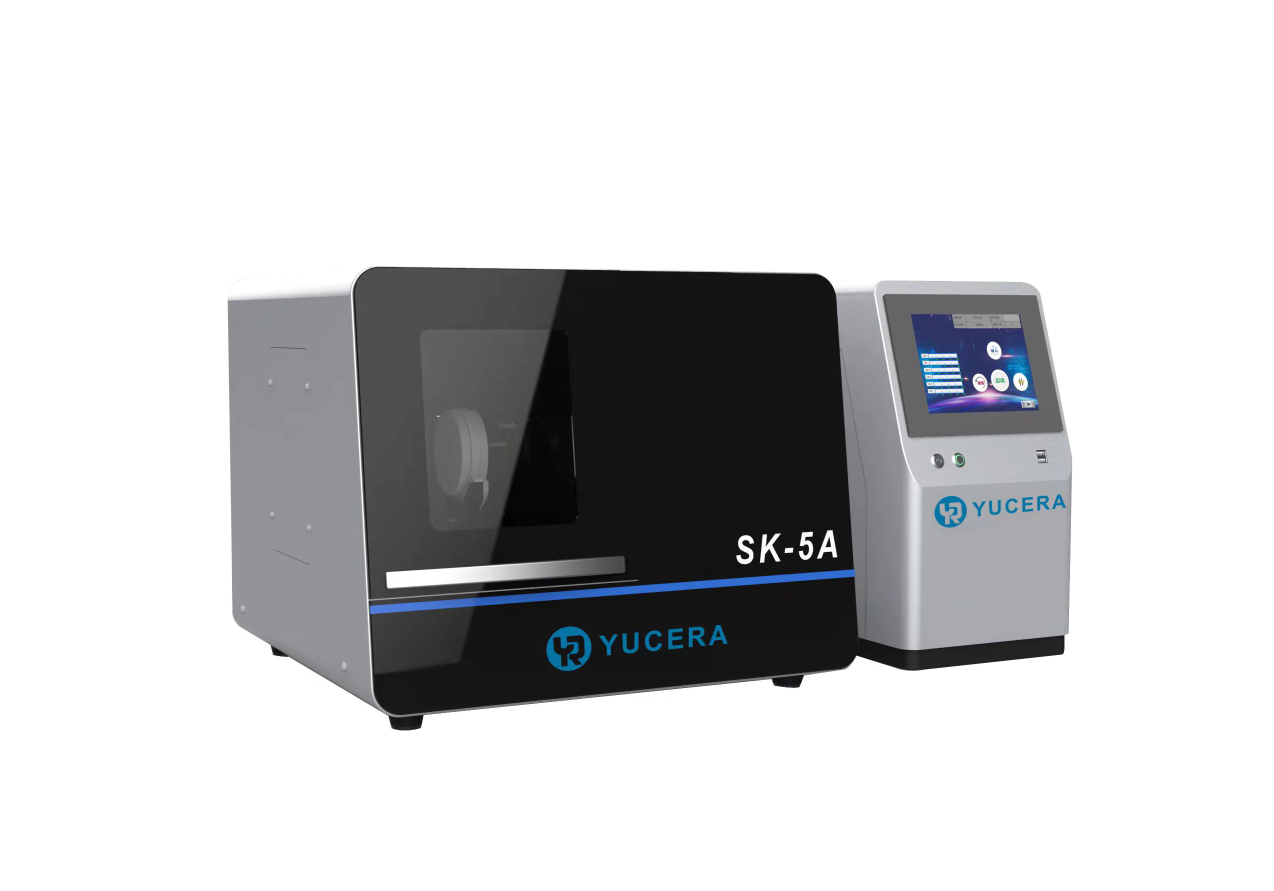

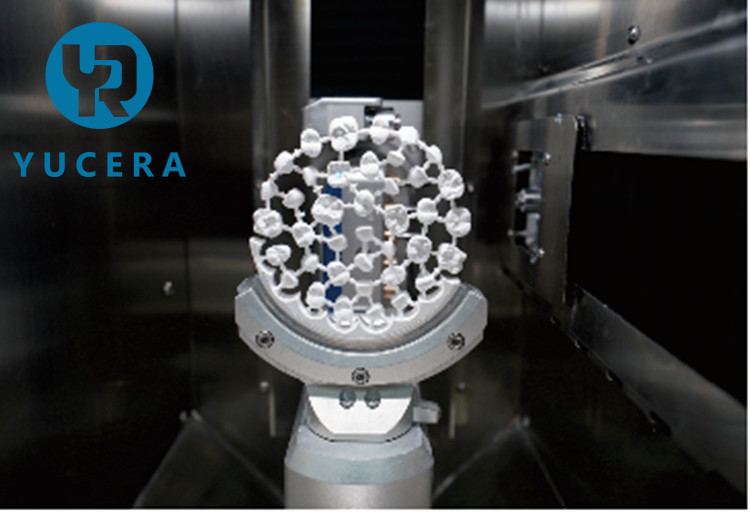

Yucera Dental Milling Machine Cad Cam System SK-5A 5axis Dental Milling Machine

Yucera Dental Milling Machine Cad Cam System SK-5A 5axis Dental Milling Machine

Product description

|

Length,wide and height

|

Cutting machine:550*565*460mm Main engine:450*250*450mm |

|

weight

|

Cutting machine:95KG Main engine:20KG |

|

Rotating axis operating angle |

A:360° B:±30° |

|

Total power

|

800W |

|

Cutting precision

|

0.02mm |

|

Tool magazine capacity

|

5 |

|

Burs specifications

|

Special props for handle diameter 4mm Automatic tool change,automatic Tool detection |

|

Processing methods

|

Five-axis linkage,dry milling

|

|

Processable type

|

Inner crowns,full crowns,bridges, Implant bridges, Implant upper restorations,inlays, onlay, veneer,coping etc. |

|

Main axis speed

|

0-60,000rmp

|

|

Working pressure

|

4.5-7.5bar (No water,no gasoline) |

|

Installation conditions

|

Stable voltage:220-230V Stable air pressure≥6.0bar Temperature:15-35℃ Relative humidity<80% |

|

Transmission interface |

USB/ethernet |

|

Milling Materials

|

Zirconia blocks,PMMA,Wax,Composite material |

Advantages

1.Split type machine; easy to maintain, reduce the damage of dust to the main engine,;and prolong the service life of the machine

2.Horizontal machine, lower center of gravity, strong stability; processing speed increased by 20%

3.Improved fixture , the utilization rate of zirconium block is increased by 30%; 38-40 units of crown/bridge can be cut at one time

Equipment maintenance

1.Regular cleaning:Use a suitable liquid detergent to clean the plastic part,and be careful not to use an air gun to clean the Interior to prevent dust and debris from entering the mechanical parts.

2.Material fixture cleaning:Clamps and screws should be kept clean when placing material for optimum grip

3.Main Axis Clip Cleaning:Do not spray oily spray or compressed air containing oil and water directly on the spindle head; The spindle chuck and bur must be clean.The entry of impurities can cause processing failures.

Usage

1.Our product can milling Zirconia blocks,PMMA,Wax,Composite material;

2.support cad cam milling

Our service

1.We have high quality after-sale service

2.Online technique support, can make a video call to help you how to operate the machine

3. 24 hours service,we have always been online

4.Fasten delivery,we are the manufacture,we can produce with faster speed

5.We promise the quality control;we are producing the product with following the CE/ISO standard